“Skin in a Syringe” Could Treat Major Wounds and Severe Burns

The innovative material aims to be a more effective an alternative to skin grafts, which often fail to address damage to the dermis – the middle layer of skin.

Researchers at Sweden’s Center for Disaster Medicine and Traumatology and Linköping University have developed a novel alternative to skin transplants for large burns and major wounds. Their “skin in a syringe”, as it has been nicknamed, is a unique hydrogel material that can coat a wound effectively while functioning as a scaffold for a patient’s own skin cells (harvested from a minimal skin biopsy) to proliferate and repair the wound.

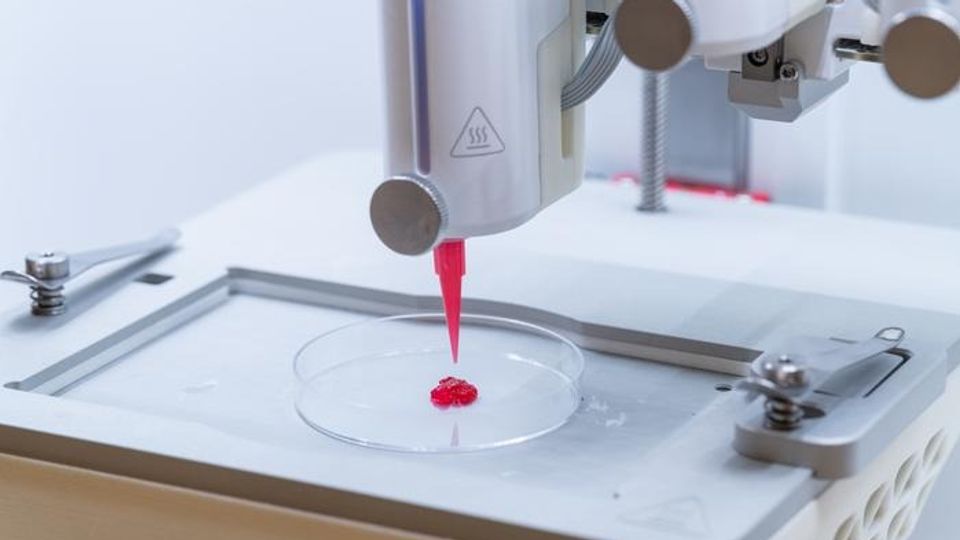

Published in Advanced Healthcare Materials, the research paper details how the scientists were able to design the hydrogel “bioink” so that it liquifies as it is being extruded through a syringe into the injury site. The material was tested by implanting small 3D-printed samples of the skin-cell-containing hydrogel bioink under the skin of lab mice, which was shown to support dermal extracellular matrix production and blood cell regrowth over 28 days post-implantation.

Dermal extracellular matrix

The dermal extracellular matrix comprises the bulk of skin and is largely made up of collagen and elastic fibers. It is a complex scaffold found within the skin's dermis that provides structural support, mechanical strength and resilience.

In a second paper, also in Advanced Healthcare Materials, the researchers report an additional hydrogel advance – the creation of hydrogel threads that can be formed into miniature tubes for pumping fluids or for growing blood vessel cells in.

To learn more about this “skin in a syringe material”, the need for improved wound care techniques and advances in the field of tissue engineering, Technology Networks spoke with study author Johan Junker, associate professor of plastic surgery at Linköping University and the director of the Advanced Medical Training Center at the Center for Disaster Medicine and Traumatology.

What are the current options available for treating burns or severe skin injuries? Why are new strategies, such as engineered hydrogels, needed?

The current standard of care for burns that are too large and/or deep for spontaneous healing is the use of split-thickness skin grafts (STSGs). This process entails the harvest of a thin (around 12/1000th of an inch) piece of skin from a suitable donor site. The STSG is then usually meshed using a skin mesher before being transplanted to cover the burn. Meshing allows a degree of expansion of the graft to cover approximately three-times the original size.

Drawbacks of STSG include the limited availability of donor sites after extensive burns, donor site morbidity and poor outcomes in the healing of the transplanted area. This poor outcome is a result of the graft being so thin, hence mainly containing the epidermis, which leaves the underlying dermis to heal by scar formation. Scars do not have the same features as normal uninjured skin, especially in terms of mechanical parameters, innervation and vascularization.

The use of in vitro autologous cultured cells to treat burns was first introduced in the 1970s, with clinical use starting during the 80s. While, in principle, this allows for the unlimited expansion of skin cells, thus enabling coverage of a large surface area, the original method (and subsequent developments thereof) have several limitations. Notably, exclusively cells from the epidermis are cultured, failing to address the limitation of scar formation in the dermal compartment. To regenerate a fully functional dermis, several cell types as well as biological microarchitecture and factors are needed. Current in vitro culture conditions fail to recreate such an environment.

By employing advanced hydrogel technologies together with pre-differentiated multicellular constructs, the healing process itself can be modulated, pivoting from fibrosis and scar formation to tissue regeneration.

What is granular hydrogel bioink? Why might this be a more promising option for dermal regeneration than other hydrogels/similar material scaffolds?

A hydrogel is a hydrated polymer network, designed to mimic the natural environment of cells in tissues. A granular hydrogel bioink is comprised of small porous spherical hydrogels (microcarriers), in this case, large enough to accommodate about 50 skin cells (fibroblasts) that are held together by a second hydrogel that acts as a glue. This allows for seeding, expansion and differentiation of cells on the microcarriers, which are then cross-linked using the other hydrogel, thus enabling the tuning of the entire construct’s material properties, while maintaining cell viability and high cell numbers.

By careful consideration of the cross-linking chemistry and the ratios of the individual components, the granular hydrogel can be used as a bioink, allowing the printing of complex shapes and architecture using a special 3D printer made for printing living cells – a so-called bioprinter.

Most importantly, the use of multicellular microcarriers producing a dermal-like extracellular matrix harnesses the natural regenerative processes responsible for normal tissue turn-over. Simplified, the cells will produce a dermal matrix instead of assuming a fibrotic phenotype that results in scar formation.

Your new advancement has been informally dubbed the “skin in a syringe”. Can you tell us more about what is special about this material that lets it switch between a liquid and gel-like consistency for easy application?

One of the most important aspects of the material is the possibility to culture and rapidly multiply the harvested skin cells on the porous microcarriers in a bioreactor before assembling the bioinks. This ensures that we can transplant dermal constructs with a high regenerative capacity.

To make sure that the cell-laden microcarriers can be easily applied to a wound with a syringe, or 3D-printed into a desired size and shape, we have modified the microcarriers to enable us to glue them together with a second hydrogel using a technology called biorthogonal click chemistry. This chemistry is fast, cell-friendly and results in materials that are soft and tissue-like.

When we apply a force, for example when extruding the material through a syringe, we physically break many of the chemical bonds that glues the microcarrier “beads” together, and the material behaves almost as a liquid. However, since we have an excess of the click-moieties, the material will reassemble and self-heal after extrusion and again resemble a soft-but-solid living material.

In one of your studies, you implanted small 3D-printed samples of the material under the skin of mice. What did this experiment show you?

The study represented the first in vivo test of this technology. Human cells were transplanted into an immunodeficient animal with the main endpoints being related to cell survival over time, blood vessel ingrowth and the formation and composition of the extracellular matrix within the transplanted constructs.

Looking to the future, how do you see this research progressing?

Currently, the project aims to validate the technology using autologous cells in a large animal model that is highly analogous to the human wound healing process. Wounds of a clinically relevant size will be transplanted using the granular hydrogel and followed for three months. We expect this study to reveal the treatment effects on wound healing and scar formation.

In a broader perspective, the technology can be adapted to other cell and tissue types, significantly broadening its application.

In second recent study, you demonstrate another unique material – mechanically robust and reconfigurable hydrogel filaments. What applications might these have?

There are three main application areas of the novel hydrogel filaments. First, it enables precise spatial control over separate cell cultures that can still be in close proximity of each other. Second, by creating perfusable tubes, oxygen and nutrients can be introduced into complex 3D tissue cultures, preventing the common phenomenon of “necrotic cores” in the central areas of larger constructs. Third, this pre-fabricated vascular network may enable microsurgical attachment of large tissue constructs to existing blood vessels in a patient, thus solving one of the biggest problems in the clinical application of tissue engineering.

References: Shamasha R, Ramanathan SK, Oskarsdotter K, et al. Biphasic granular bioinks for biofabrication of high cell density constructs for dermal regeneration. Adv Healthc Mater. 2025;14(21):2501430. doi: 10.1002/adhm.202501430

Lifwergren P, Schoen V, Naeimipour S, et al. Printing and rerouting of elastic and protease responsive shape memory hydrogel filaments. Adv Healthc Mater. 2025:2502262. doi: 10.1002/adhm.202502262