To request more information about this product, please complete the form below.

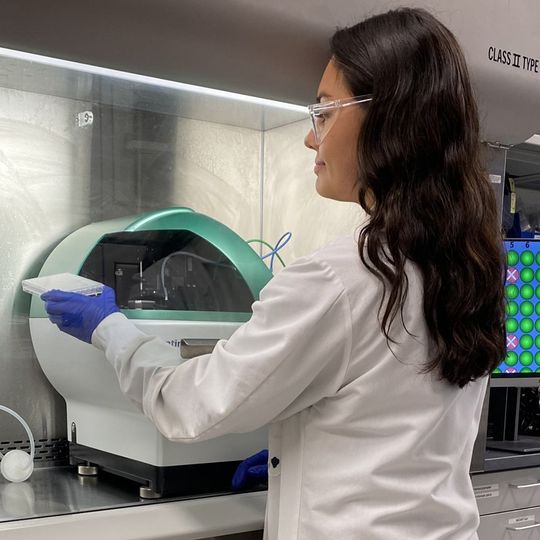

Just-Evotec Biologics Mammalian Expression System for Continuous Manufacturing

Just-Evotec Biologics is helping partners with antibody product candidates achieve the highest product quality with Cost of Goods Manufactured (COGM) below $50/g by combining its new J.CHO™ High Expression System (J.CHO™) with its unique continuous manufacturing platform. This extraordinary productivity represents a 75% reduction in industry standard COGM and is driven by the exceptionally high titers exceeding 4g/L/day in perfusion achieved utilizing J.CHO™. This performance is equivalent to a titer of approximately 30 g/L in fed-batch mode.

The J.CHO™ High Expression System comprises:

- Engineered GS knockout CHO-K1 host cell lines capable of delivering specific productivities more than 50 pg/cell/day and growing at target densities of 60-100 million cells/mL

- Transposon-based expression vectors with strong promoter sequences allowing stable integration and high expression of genes-of-interest (GOI)

- Proprietary chemically defined, protein-free and dual sourced perfusion cell culture media designed with cost-efficiency in mind.

Just-Evotec Biologics developed product sales royalty-free cell lines to work perfectly with our upstream perfusion platform process and to scale seamlessly from 3L to 500L or 1000L bioreactors for clinical or commercial production.